Biologics Process Development and Biomanufacturing Training at Sartorius

December 28, 2022 2022-12-28 4:57Biologics Process Development and Biomanufacturing Training at Sartorius

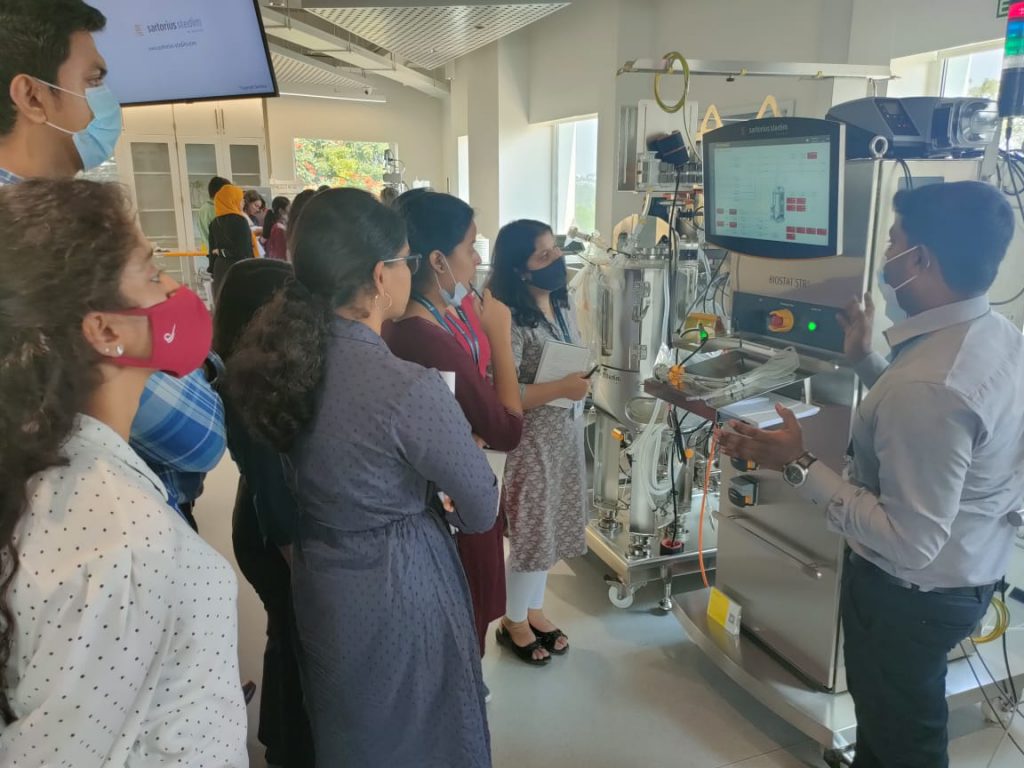

Recently the students of 22nd batch of “Biocon KGI certificate program in Biosciences” visited “Sartorius Application Center” in Bangalore for a 1-day training on biologics process development and biomanufacturing. this newly established center at Sartorius provides a collaboration area for biopharmaceutical and pharmaceutical professionals to explore process solutions and get awareness of advanced industry-specific techniques from in-house technical experts.

What was noteworthy was the hybrid nature of training wherein they covered each of the topics with a combination of presentations, videos, discussions, group activities, and demonstrating the equipment, software, set-up & accessories. The Sartorius Application center is world-class both in terms of advanced set-up having a digital classroom, touchscreen panels for discussion/feedback as well as all the latest instruments and accessories.

The students were divided into groups and were trained by technical experts in three areas namely – upstream process development technologies, downstream process development technologies, and the use of data analytics for biologics. The students understood how the industry is transitioning by adopting and implementing single-use solutions for upstream and downstream process development. They learned how cell line selection, clone screening, early process development, and characterization are carried out for biologics.

They learned about the handling of single-use bags for bioprocessing (storage bags, mixing bags, and bioreactor bags used for cultivation) and demonstrated on major components of bioreactors and their uses in dynamic operation. Students were demonstrated various Bioreactor systems (Ambr® 15, Ambr® 250, Biostat® RM, and Biostat® STR-50) used in Industry. They could understand different connection/disconnection technologies, how to control critical process parameters in bioreactor and parameterization, and got a brief overview of Process Analytical Technologies (PAT), Intermediate & aseptic sampling, and aseptic fluid transfer Solutions.

In the Downstream part, the students learned various clarification technologies for cell culture, chromatography operations for purification of Biologics (BioSMB), use of Tangential Flow Filtration (Sartoflow® Smart & Sartoflow® Advanced) in Downstream Processing, Orthogonal technologies, and Strategies for Virus Clearance, Freeze and Thaw technologies, Integrity Testing of Membrane Filters, etc.

Students were exposed to the role of Data Analytics tools like Design of Experiments (DoE) by MODDE and Multivariate Data Analysis (MVDA) by SIMCA for efficient use & improvement of upstream and downstream processing of Biologics with specific emphasis on CQAs.

At the end of the course, all the students were also awarded a certificate of participation. The commitment exhibited by the trainers along with high-quality training is worth mentioning. All the students expressed that they were enriched with such exposure to the latest bioprocess equipment, technologies, and tools used by the Biotech/Pharma Industry.

Profile:

Author: Dr. Ramgopal Rao S, Senior Academic Manager, Biocon Academy